ZQM-2L 4L Planetary Ball Mill

Application:

Pearl, ginseng, Dendrobium officinale, tablet, pharmaceutical, pharmaceutical, licorice, coke, coal, glass, cellulose, paper, chip, polymer, pigment, metal oxide, iron ore, iron powder, aluminum powder, magnesium powder, ceramics, alumina, bone, kaolin, limestone, gypsum, quartz, mineral, ore, carbide fiber, graphite, ink, clay minerals, fiber products, sewer sludge, catalyst, chemicals, alloy, soil, waste samples, wood, plant ingredients, cement slag, concrete, slag, tobacco.

Category:

You can send us an email:weicaipeng@163.com

Inquire NowNot only high appearance design, structure and system design more effectively improve efficiency and performance, the application of noise control patented technology brings more comfortable, safety use experience

Application

Pearl, ginseng, Dendrobium officinale, tablet, pharmaceutical, pharmaceutical, licorice, coke, coal, glass, cellulose, paper, chip, polymer, pigment, metal oxide, iron ore, iron powder, aluminum powder, magnesium powder, ceramics, alumina, bone, kaolin, limestone, gypsum, quartz, mineral, ore, carbide fiber, graphite, ink, clay minerals, fiber products, sewer sludge, catalyst, chemicals, alloy, soil, waste samples, wood, plant ingredients, cement slag, concrete, slag, tobacco.

Parameter

|

Name |

Planetary ball mill |

|

|

Model |

ZQM-2L(Oil seal mute) |

ZQM-4L |

|

Jar size/capacity |

25/50/100/250/500ml |

25/50/100/250/500/1000ml |

|

Vacuum jar size |

50/100/250ml/ 500ml(only stainless steel jar) |

50/100/250ml/ 500ml(only stainless steel jar) |

|

Feed Material Capacity |

16ml-160ml |

16ml-330ml |

|

How to use small jar |

50/100/250ml with a bottom tray |

50/100/250/500ml with a bottom tray |

|

Intelligent time set |

5 grinding time selections |

|

|

Feed material capacity |

1/3 capacity of ball mill jar |

|

|

Field of Application |

Pharmaceuticals, food, geology, metallurgy, agriculture, glass, ceramics, aviation chemicals, biology, materials, lithium power, electronics, plants, biology and so on. |

|

|

Feed Material |

Medium or low hardness, hard, brittle, fibrous, viscous. |

|

|

Size Reduction Principle |

Impact Force, Shear Force, Friction Force, Crushing, grinding, mixing, homogenization, alloying |

|

|

Main Disk Structure |

Planetary main disk gear invades and reinforces in lubricating oil, noise isolation treatment |

|

|

Standard |

CE |

|

|

Electrical Description |

100-120V/200-240V AC ,50-60Hz, 1PH (0.75KW) |

|

|

Material Feed Size |

< 5 mm soil<10 mm |

|

|

Final Fineness |

< 100 nm |

|

|

Batch Size / Feed Quantity |

4 x 500 ml |

|

|

Sun Wheel Speed |

10 - 400 r/min |

|

|

Ball Mill Jar Speed |

20 - 800 r/min |

|

|

Total Grinding Speed |

1200 /min |

|

|

Speed Ratio |

1:02 |

|

|

Material of Grinding Tools |

Stainless steel, agate, zirconia, corundum/alumina, tungsten carbide, nylon, polyurethane, polytetrafluoroethylene, silicon carbide, etc. |

|

|

Ball Size |

1 / 2 / 3 / 5 / 8 / 10 / 15 / 20 / 25 / 30 mm |

|

|

No. of Grinding Stations |

2 or 4 |

|

|

Mode |

Vertical planetary |

|

|

Grinding Mode |

Dry/wet |

|

|

Low Temperature Cooling Treatment |

Yes (air cooler added) |

|

|

Oil Seal Position |

The bottom of planetary main disk |

|

|

Disk Dimensions |

360 mm |

|

|

Oil Seal Capacity |

800ml(fill in before using the planetary ball mill) |

|

|

Noise |

< 60dB(Within 3 metre) |

|

|

Protection Code |

IP60 |

|

|

CN Patent |

Safety protection (No.ZL 2015 2 0836150.6) |

|

|

CN Patent |

Oil seal silent (Patent No.ZL 2014 2 0375569.1) |

|

|

CN Patent |

Frequency control(patent No.ZL 2016 2 0836150.6) |

|

|

W x H x D Closed |

780 x 580 x 680 mm |

|

|

Net Weight |

120 kg |

|

Describe

Planetary ball mill is a necessary device for mixing,fine grinding,small samples prepared,dispersion of nanomaterail,R&D of new product and small batch production for high tech materials. This equipment with small volume,comprehensive function,highly efficiency,low noise which is the ideal device of obtaining micro-particle research samples.It used for R&d institute,collages and universities,enterprise laboratory(Four samples can be obtained at the same time in each experiment). The samples could be ground under vacuum state with using the vacuum ball mill jars. Widely used in geology,mineral,metallurgy,electronic,building material,ceramic,chemical,light industry,medicine,beauty,environment protection,tea and so on.

The planetary ball mill is suitable for hard, medium hardness, brittleness and fiber materials by wet and dry methods. The fineness of the sample could be less than 100 nanometer. It can also be used for grinding solids in suspensions, sample mixing and homogenization, and metal alloying, etc. Can achieve the perfect outstanding effect.

Use of 4 ball milling jars with a volume of 50ml / 100ml at the same time.There are more than ten kinds of materials available for ball mill jars.

YXQM Series uses the latest gear noise reduction technology and the completely closed oil seal patent technology noise isolation design to control the noise when running and is more stable than the ordinary planetary ball mill.Increase life by more than five times(Patent No.ZL 2014 2 0375569.1)

Effectively enhance the comfort of laboratory use, high efficiency sample processing capacity, unique appearance and structure design, strict production process to help MITR technology become one of the international excellent, popular sample preparation products.

Size Reduction Principle

Under the action of the geometric structure of the grinding carrier and the special motion mode, the high frequency, high strength collision, shear and friction produced directly between the grinding medium and the sample make the sample achieve excellent grinding effect. It has the characteristics of fast processing speed, small granularity, uniformity and uniformity.

1.Moving:The materials are away from the center of revolution as a whole in a group way, and then turning to a certain angle with the cylinder rotation, sliding in the opposite direction of rotation, the grind ball pushes the powder layer on the mill, exerts compression, shear and friction on the material.

2.Throw drop:When the material is transferred to a certain angle with the grinding cylinder, the pressure on the cylinder wall is equal to that of leaving the wall temporarily and the material is impacted.

3.Circulation:The material rises along the concentric circle trajectory, and then falls down layer by layer, showing the state of circulation. The powder is extruded and ground and rubbed by friction.

4.The material moves in a circular motion with the grinding ball and slips with it, the powder is rubbed by friction.

5.The material on the cylinder wall cannot be comminuted without the sliding of the grinding tube, but it can be used to protect the inner wall of the grinding cylinder and reduce wear.Which act as ultra fine grinding is mainly the circulation and sliding motion.

Feature

1.Small volume, structure using thickened steel plate, shell using thickened plate, vibration resistance, smooth, sound insulation, safety, internal and external spray-paint treatment;

2.Adopt patent technology of oil seal and noise-reducing material to reduce noise and improve comfort.

3.Automatic processing, no need to debug, simple to use, practical and comprehensive function

4.Low power, low loss, low cost, low fault

5.European standard conical drive wheel, European standard electrical parts and circuit design, brand inverter, electric and other high standard accessories to ensure quality and service life;

6.The impact energy is strong, the discharge is more uniform, the precision is higher, the crushing ability is stronger, the granularity of the sample is finer and the processing speed is faster.

7.Can set grinding time, intermittent time, movement direction, movement speed, and has power loss memory, emergency stop, overload protection function

8.Long service life, strong safety, can meet the requirements of long time and high strength experiment.

9.25ml 50ml / 100ml, different volume ball mill can be universal, increase sample treatment quality and size of the interval

10.Stainless steel, nylon, polyurethane, polytetrafluoroethylene, zirconia agate and other more than 10 different materials of ball milling tank to provide a choice, grinding samples more extensive;

11.Samples can be dry and wet grinding, and can be equipped with vacuum ball mill tank for vacuum grinding, pressurized mill, inert gas grinding

12.Reconfigurable liquid nitrogen cryogenic system for ultra-low temperature treatment (additional function)

13.It can realize the detection of temperature and pressure in the ball mill carrier (add function).

14.Up to 4 different kinds of samples can be lapped simultaneously in 4 ball milling tanks, and 2 ball milling tanks can be placed symmetrically.

15.Under the same conditions, when several ball milling tanks grind the same sample at the same time, each ball mill tank has the same grinding effect on the sample.

16.Under the same conditions, the effect of grinding the same sample in each batch is the same.

17.The application involves the industry all round, the grinding sample type involves a wide range, the grinding flexibility is strong

Accessories

In the use of the planetary ball mill, the sample processing needs to be carried out in the ball mill carrier through the action of the grinding medium. Therefore, the ball mill jar and the ball mill media are indispensable and main accessories of the planetary ball mill. There are more than ten kinds of different materials and more than 200 kinds of experimental schemes of ball mill carrier and milling medium developed by MITR Technology which can be combined and selected. Different treatment results can be achieved when the samples with different physical and chemical properties are treated.

Ball mill jar optional material

|

● Stainless steel jar(304/316) |

●Tungsten carbide jar(WC) |

● Nylon jar(MC) |

● Polyurethane jar(PU) |

|

● Polytetrafluoroethylene(PTFE) |

● Polypropylene jar(PP) |

● Nylon(PA) |

● Zirconium jar(ZRO) |

|

● Alumina jar(ALO) |

● Agate jar(SIO) |

● Silicon Carbide jar |

● Stainless steel vacuum jar |

Special ball mill jar for vacuum / inert gas protection:

|

● Vacuum jar lined agate jar |

● Vacuum jar lined tungsten carbide jar |

● Vacuum jar lined zirconium jar |

|

● Vacuum jar lined nylon jar |

● Vacuum jar lined alumina jar |

● Vacuum jar lined polyurethane jar |

Balls material

|

● Stainless steel(304/316) |

● Agate(SIO) |

● Tungsten carbide(WC) |

● Zirconium(ZRO) |

|

● Alumina(ALO) |

● PTFE |

● Polyurethane(PU) |

● Columnar zirconium ball(ZRO) |

The MITR Lab 1000 sets of application cases led by Dr. Peng Weicai of the Institute of Fine Metallurgy of Central South University for 60 years of academic succession and continuous innovation of MITR. Meanwhile, MITR Labs provides you with free sample grinding.

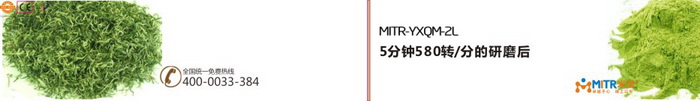

Tea, hay and other herbs: light, fluffy crushing and grinding

Fiber: fibrous, crushing and grinding with a certain tensile strength

Soil: crushing and grinding of soil sand with different physical properties

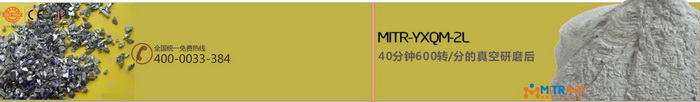

High purity metal: granular, hard, oxidized high purity powder in vacuum atmospheres

Quartzite: crushing and grinding of granular, hard materials

Display

|

● Alumina jar used |

● zirconium jar used |

|

● Stainless steel jar used |

● Polyurethane jar used |

|

● Nylon jar used |

● Agate jar used |

|

● Patents and CE certification |

● Patents and CE certification |

Previous

Previous